Werk/Schau

Dienstag, 5. Dezember 2017

Soon: home automation

Klick-Klack

We bought a home and are busy renovating for month now. I will eventually start to post more again, presumably over home automation stuff. ^^

The pic shows my test of an 40 year old thermostat driving an equally old air-valve for our heating system.

Montag, 5. Juni 2017

More power!

I'm was not publishing that much over the last few month. That doesn't mean that I'm not doing anything though.

This is a project which I wanted to finish in March - that means before we started our camping trip to Corsica. I didn't because I was a bit spooked by the amperage a 800W inverter can draw and wanted to do it right. But now it's done.

You are looking at the plug and operating panel of the 220V inverter I put into our car. I used a AEG ST 800 inverter with has this handy remote control panel. It's placed under the driver seat of our Mercedes Viano (2006). The inverter has a fan which nicely matches up with cooling vents under the seat, and its right beside the car battery so it's in the perfect place.

The electrics are as follows:

- 10mm2 wire from the battery to a 50A fuse

- from there over 6mm2 to a relay connected to the switch

- the relay switches the inverter and the usb charger, which lights up when switched on (power light)

The cooling vents in the seat were handy, but they were only present in the metal box below the plastic covers... so I lasercut some vents in them (to the right). The plastics material was PP.

Mittwoch, 31. Mai 2017

Saw

An old buzzsaw in a workshop at a mountain farm in eastern tyrol in Austria.

Made with my Pentax 645N.

Dienstag, 31. Januar 2017

Furious dice bag

A friend of mine started a new Youtube channel(-> here) about his pen-and-paper RPG endeavours. In fact, he already has such a channel (-> here), but the new one if in english for a broader reach.

Anyway, I like when people do something other than sit in front of Facebook, so I made him a gift:

A leather dice bag, made with the laser cutter in the MunichMakerLab!

The first leather dice bag I made... and it kinda sucks! :-D

I wanted to engrave his new logo, sadly I didn't watch the paths and didn't realise that the thick black areas were lots of paths side by side. So the laser penetrated not just engraved. Well it still holds together but I don't know how long

Second, the rope doesn't glide. I sew a narrow strip of leather together and wanted to turn it out... didn't work, to narrow. I had no alternative, so I put it in like that.

With all that I forgot to make nice endings for the rope, so I set four stitches by hand to just fold it over.

Meh, could be worse. Next one will be better!

Samstag, 31. Dezember 2016

It ends with a bang

Yet another discard from the 3x17 photo project. And the last one, because after a year of weekly challenges the project is done. Sad and happy at the same time...

Montag, 19. Dezember 2016

Hydroponic board

Well, sometimes you have to admit failure. I shelved the wheel, the soft micro greens I want to grow do not like the rotation much. So I went and bought the IKEA VÄXER system.

I didn't bought the light they sell though. I used their light fixture and just glued some blue and red leds under it. Much cheaper.

The plants moved over to the new system an are much happier now. The first harvest was quite tasty.

Samstag, 19. November 2016

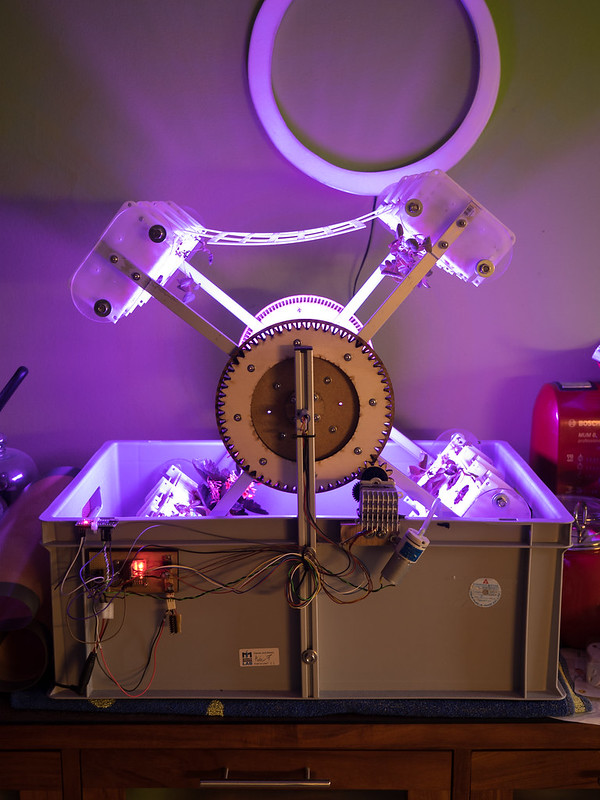

Hydroponic wheel

I would love to be able to grow my own salad. Thanks to hydroponics that could be possible even in our small, inner city flat. That is a growing trend I suppose. IKEA started bringing out Hydroponics products just recently (I didn't know that before I started).

I was even more fascinated by wheel based hydroponics. In normal hydroponics you move the water level up and down to give the roots some air. In wheel based hydroponics you move the plants. Benefits: Better light/power use, less complicated water works.

I had a deadline of about 4 weeks to the MunichMakerLabs exhibition at the Steet Live Festival in Munich. And despite lots of work, I did it. =)

Frame:

The frame is based on a sturdy plastic bin bought in a hardware store. The wheel arms are maker beams that were sitting around in the Lab. The arms are screwed into the bin, the screwheads on the inside are sitting on a thick rubber plate to keep the water in. There is a central rod between the arms, made out of 8mm stainless steel. The light tube is attached to this central rod.

The frame is based on a sturdy plastic bin bought in a hardware store. The wheel arms are maker beams that were sitting around in the Lab. The arms are screwed into the bin, the screwheads on the inside are sitting on a thick rubber plate to keep the water in. There is a central rod between the arms, made out of 8mm stainless steel. The light tube is attached to this central rod.Wheel:

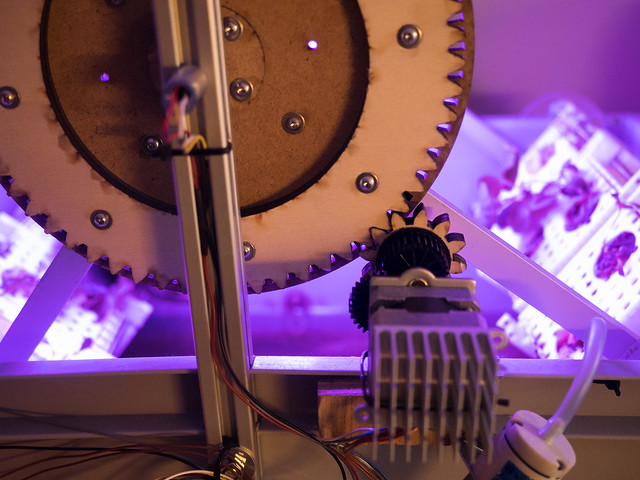

The wheel is sitting on this central rod on ball bearings intended for a long board. Everything thats coming in contact with water is made from aluminium, stainless steel or acrylic. The hub consist of four lasercut center plates (+ one gear ring) with four arms each to carry the pods. Another four arms can be attached between the existing ones to increase the density. At the end of the arms are thick acrylic plates with two robs connection to the other side. These rods carry the Pods.

The Pods are lasercut acrylic cages, stuck together (without glue). The are holding a ball of rockwool into which the plants can grow into. The pods are made to be taken out from outside the wheel. Two small sliders lock it down.

The Pods are lasercut acrylic cages, stuck together (without glue). The are holding a ball of rockwool into which the plants can grow into. The pods are made to be taken out from outside the wheel. Two small sliders lock it down. Electronics:

The motor is a multi-geared stepper motor from an old printer. Its driver by a extremely cheap stepper driver and an arduino. Everything is connected to a common 12V rail (the thing was designed to be driven from a car battery...). The wheel is very slowly turning and makes one rotation each hour.

Light:

The central light tube is attached to the central rod and is not turning with the wheel. Its made out of a plastic tube wrapped with three parallel led strips (two red, one blue) and then covered with clear foil to prevent water dripping on it.

The project is running for ~2 month now. Its working well and stuff is growing. But there are some problems:

- Some of the plants I want to grow (leaf salads, basil and other herbs) have very weak stems and some of them can't cope with the movement of the wheel. Further trials are needed. Maybe going even slower helps. And/or something to stabilise the seedlings.

- The water needs to be changed every two weeks or it will bread algae. This is a lot of work as the volume is around 20 litres. And it means throwing away lots of fertilizer. The water basin needs to be covered.

- The light source is not bright enough. More LEDs!

Sources:

Github repo will be created soon...

Sonntag, 6. November 2016

Sonntag, 18. September 2016

Thats not pink!

A friend gave me an old pink magenta pedal car for my son, as thank you for helping them move.

It's made out of sheet metal any already survived his two son more or less unscratched.

The only (major) thing that's not made out of metal is the seat (you can see the original here), so I decided to change build a leather seat.

The only (major) thing that's not made out of metal is the seat (you can see the original here), so I decided to change build a leather seat. I used fantastic plastic as a base material, found some foam at the makerspace and used some furniture leather I had sitting around as cover. I made it a twin seat because, you never know If you need some additional room. =)

Sonntag, 5. Juni 2016

Abonnieren

Posts (Atom)